Biodesign: Living and Breathing the Future of Performance, 2018 May

PUMA + MIT Design Lab collaboration for Milan Design Week

*Jiwon Woo as a Biodesiger, Project Coordinator and Exhibition Designer

MIT Design Lab

Milan Design Week 2018

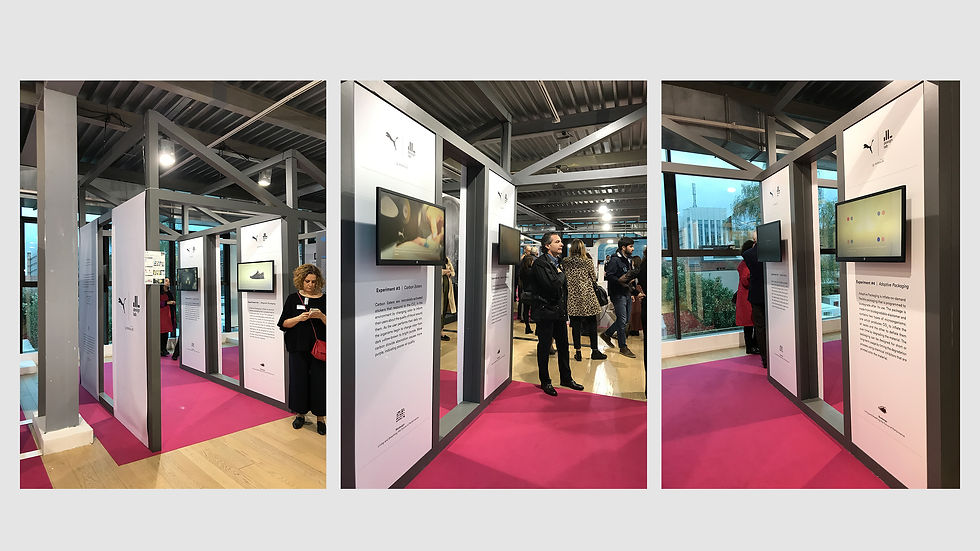

As a member of the MIT Design Lab, Woo took the roles of a biodesigner, project coordinator, and exhibition designer for PUMA and MIT Designer Lab's collaboration project on biodesign.

At Milan Design Week 2018, PUMA and MIT Design Lab showcased ongoing research in the field of biodesign. Powered by Biorealize, the exhibition focused on how the next generation of wearables can adapt in real-time using living organisms to enhance performance and personal expressions. Bridging the worlds of biology, design, and technology, using living materials such as algae, bacterial, or yeast, the research explored the new frontiers of fabrication to bring biodesign closer to our daily lives through sport products. Powered by Biorealize desktop bio-prototyping platform, the exhibition focused on how the next generation of wearables can adapt in real-time using living organisms to enhance performance and personal expressions. The exhibition showed four experiments: 1) Breathing Shoe, 2) Deep Learning Insole, 3) Carbon Eaters, and 4) Adaptive Packaging.

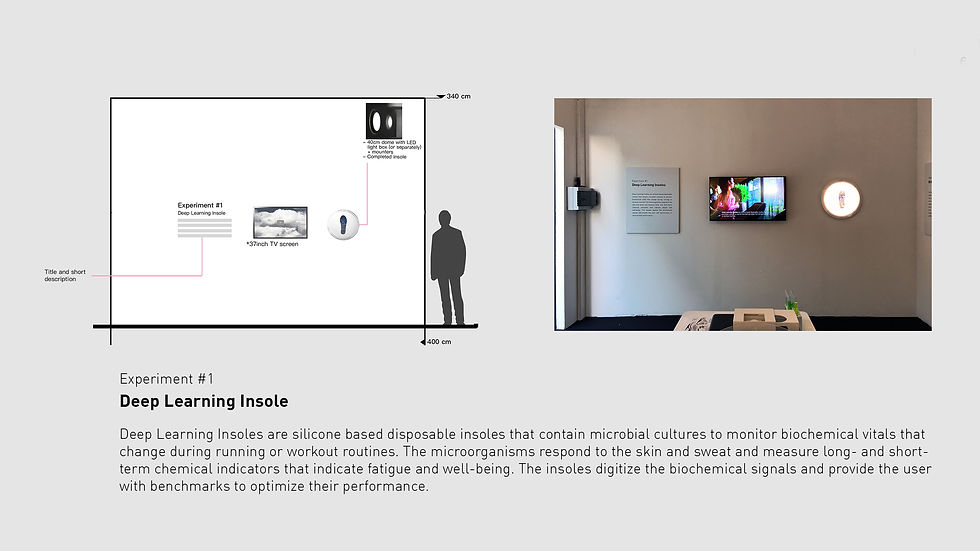

Deep Learning Insole

-

With next generation Deep Learning Insoles we show how real-time biofeedback can prevent fatigue and improve athletes’ performance.

-

Deep Learning Insoles are silicone-based disposable insoles that contain microbial cultures to monitor biochemical vitals that change during running or workout routines. The microorganisms respond to the skin and sweat and measure long- and short-term chemical indicators that indicate fatigue and well-being. The insoles digitize the biochemical signals and provide the user with benchmarks to optimize their performance.

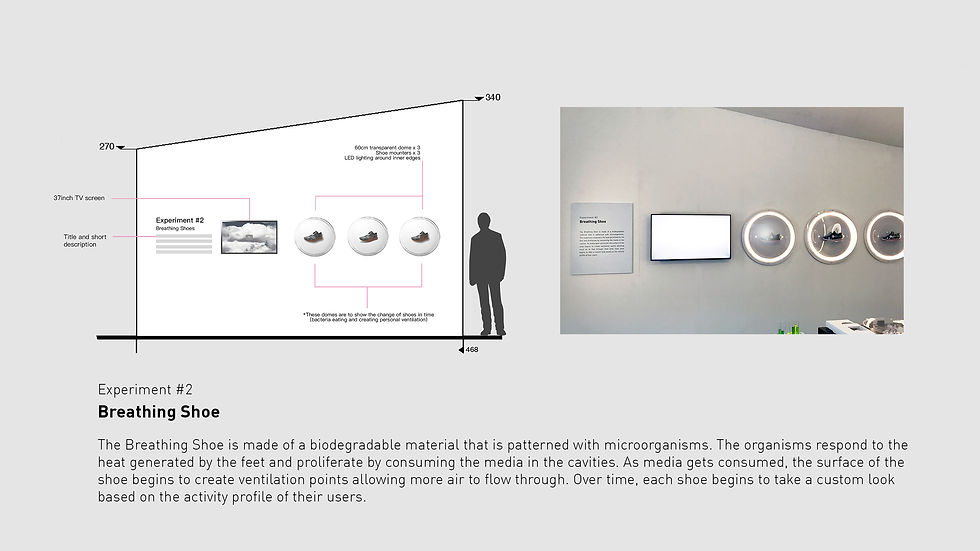

Breathing Shoe

-

Biologically active Breathing Shoe pushes the boundaries of bio-fabrication and enables personalized ventilation by growing their own air passageways.

-

The Breathing Shoe is made of a biodegradable material that is patterned with microorganisms. The organisms respond to the heat generated by the feet and proliferate by consuming the media in the cavities. As media gets consumed, the surface of the shoe begins to create ventilation points allowing more air to flow through. Over time, each shoe begins to take a custom look based on the activity profile of its users.

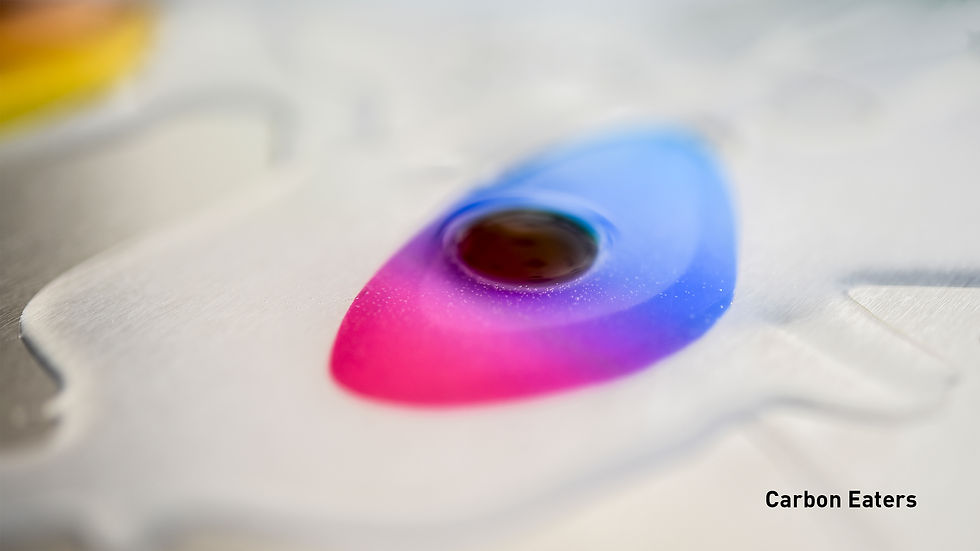

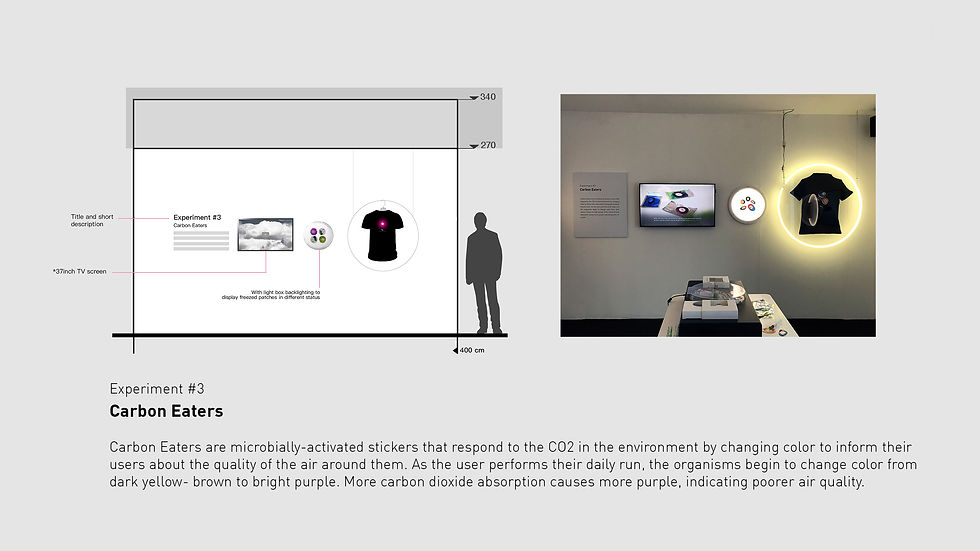

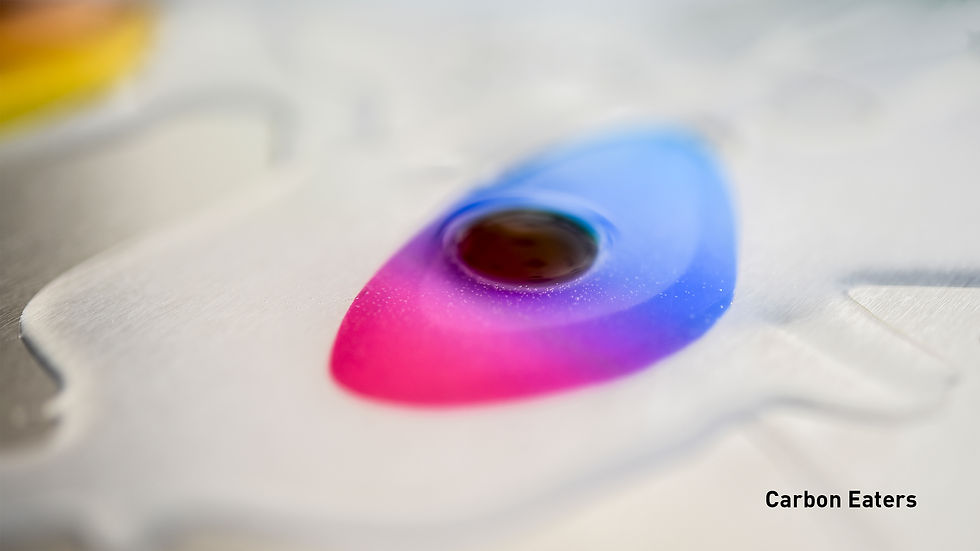

Carbon Eaters

-

Carbon Eaters, a microbially-active tee responds to environmental factors by changing its’ appearance and informing the user about air quality.

-

Carbon Eaters are microbially-activated stickers that respond to the CO2 in the environment by changing color to inform their users about the quality of the air around them. As the user performs their daily run, the organisms begin to change color from dark yellow-brown to bright purple. More carbon dioxide absorption causes more purple, indicating poorer air quality.

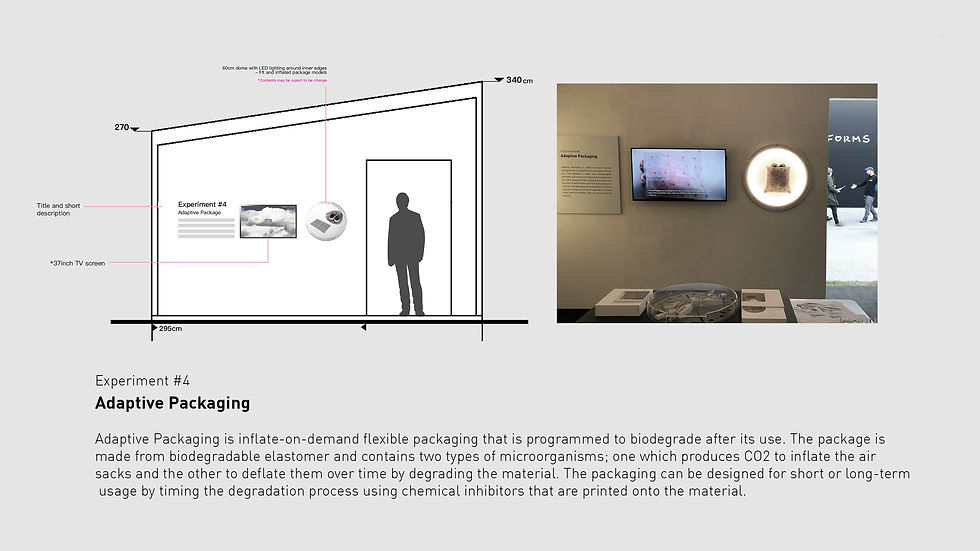

Adaptive Packaging

-

Thinking beyond current wearables, PUMA and Design Lab featured biologically programmable materials that change their shape and structure to become new types of alive, biodegradable, and Adaptive Packaging.

-

Adaptive Packaging is inflate-on-demand flexible packaging that is programmed to biodegrade after its use. The package is made from biodegradable elastomer and contains two types of microorganisms; one which produces CO2 to inflate the air sacks and the other to deflate them over time by degrading the material. The packaging can be designed for short or long-term usage by timing the degradation process using chemical inhibitors that are printed onto the material.